Sigma Unloader: Coming Soon

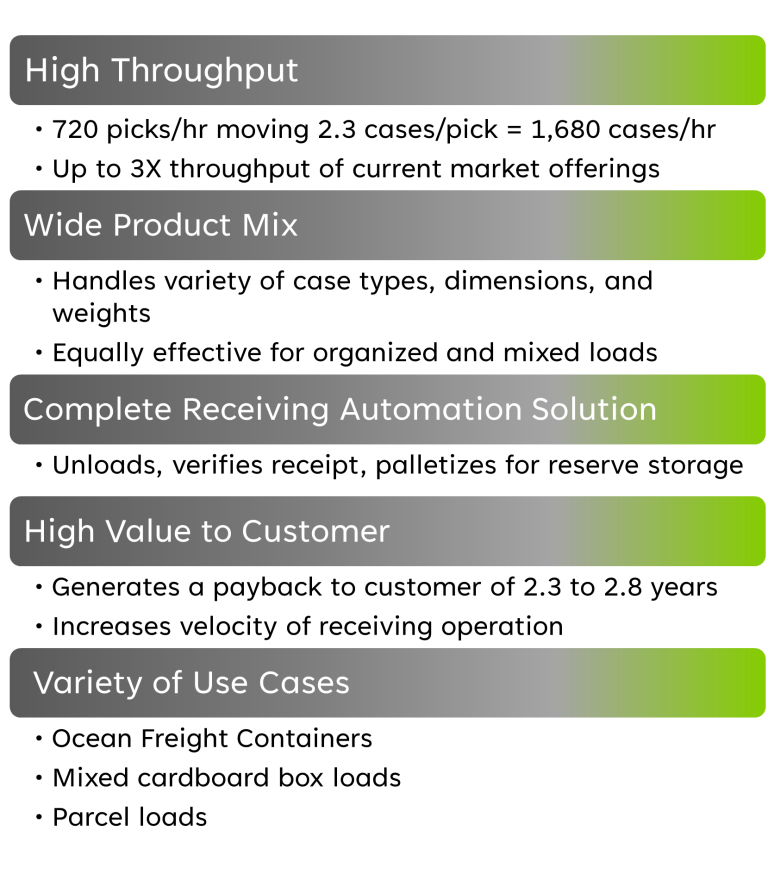

The Sigma Unloader is a robotic trailer unloading system that aims to automate the unloading of goods from trailers and containers, thereby enhancing efficiency and safety in warehouse operations. This system employs advanced robotics and artificial intelligence to identify and handle items, which reduces the need for manual labor. The task of unloading can be physically demanding and time-consuming, and finding qualified and willing workers for these tasks is increasingly challenging. The primary issue with the robotic unloaders currently available on the market is their insufficient throughput, which does not justify the replacement of manual unloading. Additionally, they struggle to adapt to real-world loading conditions and to manage a diverse range of product sizes and packaging types. AlphaOne Robotics is introducing new technology to transform the trailer unloading landscape.

,AlphaOne Robotics is revolutionizing the logistics industry with its state-of-the-art robotic truck unloader. This groundbreaking technology boasts a throughput that is 2 to 3 times higher than current unloaders available in the market. Remarkably, the throughput of AlphaOne’s robotic unloader not only matches but often exceeds that of manual operations. This leap in efficiency is a game-changer, offering unprecedented speed and precision in unloading tasks. By integrating AlphaOne’s robotic solutions, businesses can significantly enhance their operational efficiency, reduce manual labor, and stay ahead in the competitive logistics landscape.

For more information about our robotic unloading solution, please contact us, and we will furnish the details under a non-disclosure agreement.

Email to get more information

Automotive Tire Loading and Unloading

Robotic loading and unloading of automotive tires is a cutting-edge technology that automates the handling of tires in the automotive industry. These systems use advanced robotics and AI algorithms to efficiently load and unload tires, reducing the need for manual labor and increasing throughput. The benefits to the market are significant:

Increased Efficiency: Robotic systems can operate continuously without fatigue, leading to higher productivity.

Improved Accuracy: Robots can precisely handle tires, reducing the risk of damage and ensuring the right tire goes to the right place every time.

Enhanced Safety: By automating the heavy lifting, the risk of workplace injuries is significantly reduced.

Cost Savings: While there’s an initial investment, over time, the increased efficiency and reduced labor costs can lead to substantial savings.

By integrating these robotic systems, businesses in the automotive industry can significantly enhance their operational efficiency and competitiveness.

AlphaOne Robotics is at the forefront of innovation with its robotic tire loader and unloader, specifically designed to meet the evolving needs of the automotive market. This advanced system leverages robotics and AI to automate the process of loading and unloading tires, significantly enhancing operational efficiency. The system operates continuously, offering increased productivity and improved accuracy in tire handling. It also ensures enhanced safety by eliminating the need for manual heavy lifting, thereby reducing workplace injuries. Moreover, the system provides substantial cost savings over time due to its efficiency and reduced labor costs. AlphaOne Robotics’ solution is a testament to the power of automation in transforming the automotive industry, addressing market needs, and driving competitive advantage.

Email to get more information

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.